From time to time we invite guest writers to our blog to talk about subjects in which they are well versed. This time we welcome David Parton-Ginno, a Sales Engineer for Xylem Analytics UK, to talk about quality control within the food and beverage industry. His insights are backed by deep product knowledge as well as a personal history that includes employment within food & beverage.

Looking for standards in food & beverage

We don’t have to look too far into the past to see that quality control within food and beverage manufacturing differed from factory to factory, company to company; with very little in the way of standardisation between companies manufacturing the same or similar products.

During my career, I was fortunate enough to sit on the Lab of Government Chemist (LGC) ring testing committee. During this time, I discovered that our competitors and even sister sites had very different approaches to quality analysis – so much so the LGC struggled to come to a consensus on the testing methods of the standards they were creating.

Fast forward to more recent years and this has changed considerably, the industry is now employing multiple analysis techniques and utilising a range of instruments to provide due diligence and to meet HACCP requirements. Proving that your products are manufactured to the highest standard has become expected and is routinely assessed by bodies such as the British Retail Consortium (BRC) and European Food Safety Inspection Service (EFSIS), against increasingly more stringent standards and they encourage standardisation across the industry.

Working directly for a beverage manufacturer and later selling into the Food and Beverage Industry, I have garnered an insight over the multiple years that many don’t have the privilege to see.

Like countless others, the company that I worked for started its life using a variety of equipment, (that could very loosely be described as “analytical”) mostly obtained from the brewing industry or brewery suppliers. The equipment was often barely fit for purpose for use with soft drinks and regularly modified to make it so. However, at the time it was all that seemed to be available.

As time progressed, kit was upgraded to include the Bellingham + Stanley RFM81 Refractometers and Schott® Titrators, and eventually to the Bellingham + Stanley RFM340 and SI Analytics TitroLine® titrators – leading the way throughout the food and beverage industry many followed suit in providing quality control (QC) testing facilities. Mistakenly however, some opted for basic low accuracy handheld refractometers and manual burette methods to reduce costs.

While low cost, low accuracy instruments are reasonably acceptable in some applications, they are not always best suited for large scale production facilities. In modern companies’ profit is at the forefront of nearly all business decisions, and food and beverage manufacturers are, sadly, often no exception. Therefore, buying low-cost options for your quality control lab is often not the best policy.

While low cost, low accuracy instruments are reasonably acceptable in some applications, they are not always best suited for large scale production facilities. In modern companies’ profit is at the forefront of nearly all business decisions, and food and beverage manufacturers are, sadly, often no exception. Therefore, buying low-cost options for your quality control lab is often not the best policy.

Taking a leaf out of the car makers book, many food and beverage companies have now implemented quality systems such as Kaizen and Six Sigma through the manufacturing plant to boost productivity, reduce waste and improve yields.

Conversely, the implementation of these quality systems often neglects to consider the accuracy of the QC instruments, leading to a level of frustration within the implementation team.

Instrumentation for quality control

It has long been known that improving yield increases profitability. However, to achieve this, there needs to be a delicate balance between consistency of product whilst making sure over dilution (or over-Brixing) doesn’t occur.

So how do you increase the yield of your product by replacing your old inaccurate QC equipment with more suitable instrument without the huge price tag?

There are a few things to consider when replacing old analytical equipment for new instruments, these being: -

- Accuracy – the closeness of the measurements to a specific value.

- Precision (Reproducibility) – the ability to achieve the same results repeatedly

- Resolution – the smallest interval measurable

- Temperature – product, environmental and measurement

- Substrate – product you are measuring

- Time – the length of time to perform analysis

- Suitability – is it fit for purpose

The above considerations affect the outcome of the measurements (Results) – opting for the highest in everything would be costly and unlikely to be fit for purpose, therefore suitability is a balance between all these consideration –this is why Xylem offers a wide range of instrumentation.

A more accurate, better suited instrument gives greater confidence in the results you obtain too.

Coupling the touchscreen Bellingham + Stanley Peltier controlled RFM340-T Refractometer with the SI-Analytics Titroline® 7000 is a perfect way to improve yields.

By measuring these two parameters in tandem you can devise the overall product quality very quickly.

For example, let’s take a can of a well-known branded Cola, we could use acidity titration to determine the levels of phosphoric acid, too high or too low could result in taste issues, product destabilisation, discolouration (bleaching) and even microbiological growth – With a refractometer we could determine Brix (amount of sugar present) and suspended/dissolved solids from the Refractive Index (RI) showing an estimate of the level of other ingredients within the Cola

From two basic parameters, we can obtain within a few minutes an understanding of the makeup of the product, and if it has been made to the correct recipe. This can be done by the operator on the factory line without the need to run expensive and time-consuming diagnostic analysis such as HPLC within a dedicated laboratory.

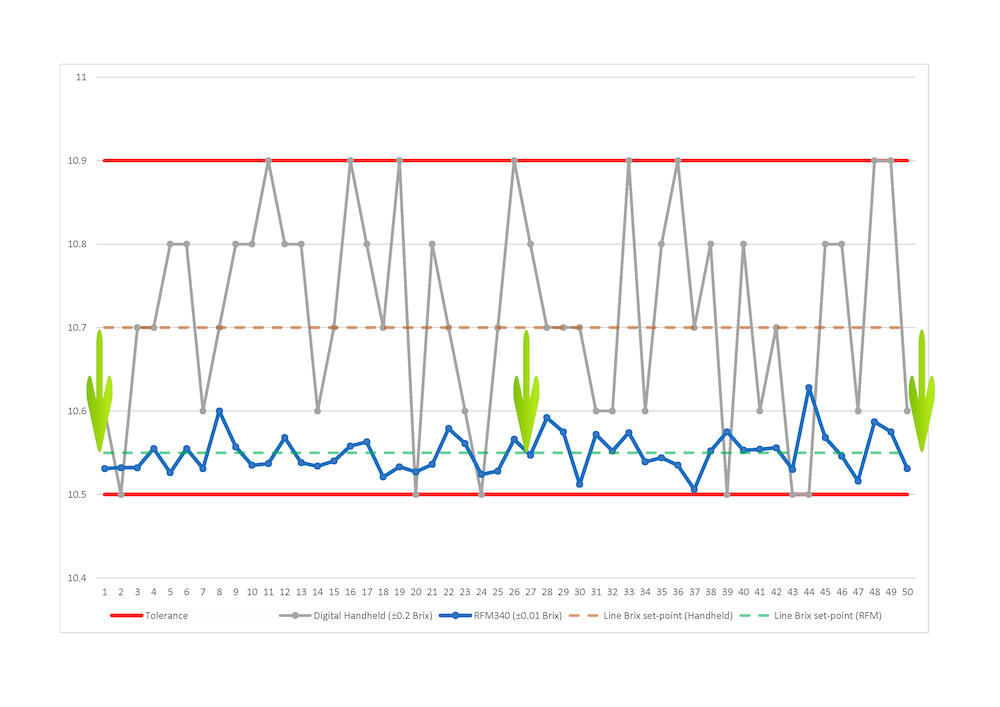

Image above: Soft drink yield comparison - Handheld vs High Accuracy Desktop Refractometer

Managing the product directly on the line means more samples can be taken on a regular basis and as analysis can be done within in few minutes this means the operator can make regular micro adjustments on the filler, ensuring product quality is met while increasing the yield of the product – Better yield gives you more selling units per batch, which equals more profit plus a better-quality product that you sell more of.

Win-Win!

Food & beverage analysis and quality control instrumentation

There are many different options available to you and browsing our website is a great place to start. However, if you’re looking for a complete solution tailored to your business or unique application then please get in touch. Bellingham + Stanley, and SI Analytics are a part of Xylem Analytics, whose brands have been serving the food & beverage industry for over 100 years. Together these brands offer deep application expertise from decades of leading innovation with products, systems and services that address the full cycle of food and beverage production.

To discuss how Xylem can help you improve your yields, contact us today.

David Parton-Ginno has over 30 years of scientific and laboratory experience and is a Sales Engineer for Xylem Analytics UK. David has been with the company for 2 years working with B2B customers at all levels. His expertise within the food & beverage industry (among others) has helped numerous customers solve problems and overcome challenges with instrumentation workflows, and quality control.

To contact David directly please email David.Parton-Ginno (at) xylem.com.